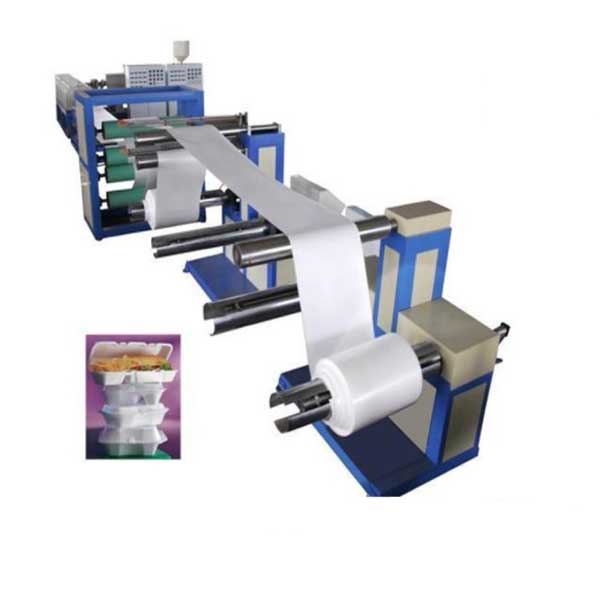

Product Profile

The PS foam sheet extrusion line adopts the double-machine tandem high-foaming sheet production process. The PS foamed sheet produced is a new type of packaging material, which not only has good heat insulation and cushioning properties, but also has a pearl-like appearance and color. It has the advantages of shock resistance, sound insulation, heat preservation, moisture resistance, safety and hygiene, and plastic absorption. After vacuum thermoforming, it is widely used in the packaging and advertising boards of various products such as English and food, fruit, electronics, daily necessities, and hardware products.

PS foam sheet extrusion line Process flow:

1. General-purpose polystyrene particles plus ingredients and mixing

2. The mixture enters the No. 1 machine (injecting foaming agent)

3. Screen changer (filter)

4. The raw material enters the No. 2 machine

5. The sheet is extruded from the die

6 Cooling and shaping

7. Traction

8. Rewind

9. Finished product

10. Packaging

PS foam sheet extrusion line specification:

|

parameter |

unit |

model |

|||

|

capacity |

Kg/h |

80-100 |

200-240 |

230-260 |

280-360 |

|

Sheet thickness |

mm |

1-4 |

1-4 |

1.5-5 |

2-5 |

|

Sheet width |

mm |

640-1080 |

640-1080 |

800-1080 |

900-1080 |

|

Foaming rate |

10-22 |

||||

|

Cooling method |

Wind&water cooling |

||||

|

Cutting method |

Single cutting |

||||

|

Butanegas pressure |

mpa |

0.9-1.2 |

|||

|

Installation power |

m |

24*6*3 |

30*6*3 |

32*6*3 |

35*8*3 |

|

Powder supply |

|

3phase 380V 50HZ/3phase 220V 60HZ |

|||

can not be empty

The E-mail format is not correct

can not be empty

can not be empty